Description

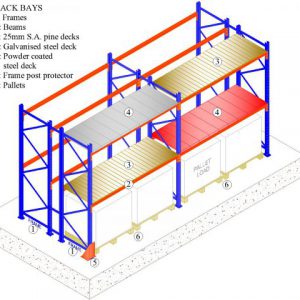

Drive In Racking

Drive In Racking, it reduces the volume of conventional traffic aisles, ensuring maximum use of space for high-density, floor-to-ceiling palletized storage.

Drive-In Racking:

- Vehicle Access: Permits vehicles to enter the storage area for pallet placement in a back-to-front arrangement.

- Efficient Retrieval: Allows the operator to back out of the rack after pallet placement.

- Ideal for FILO: Best suited for “FIRST-IN / LAST-OUT” inventory management.

- Double-Entry Systems:

- Can be designed in a back-to-back arrangement.

- Increases density and allows for entry on both sides of the system.

Drive-Through Racking:

- Dual Access Aisles: Features two access aisles for loading and retrieval.

- Streamlined Operations:

- Lift trucks can pass through the rack bay, placing loads on supporting rails from one side.

- Trucks can exit in the same direction or enter from the opposite side to remove loads.

- Ideal for FIFO: Well suited for “FIRST-IN / FIRST-OUT” inventory movement.

Advantages of Both Systems:

- High-Density Storage: Both Drive-In and Drive-Through systems offer the capability for high-density storage.

- Cost Efficiency: Lower operational costs due to optimized space usage and reduced need for additional square footage.

- Improved Workflow: Enhanced efficiency leads to faster inventory turnover and reduced labor costs, contributing to increased profitability.

In summary, Drive-In and Drive-Through racking systems are essential for any warehouse aiming to enhance storage capabilities and streamline inventory management processes. Their ability to optimize space and improve operational efficiency makes them top choices for modern storage solutions.

Click Here to view our other racking systems!

Click to rate this post!

[Total: 0 Average: 0]